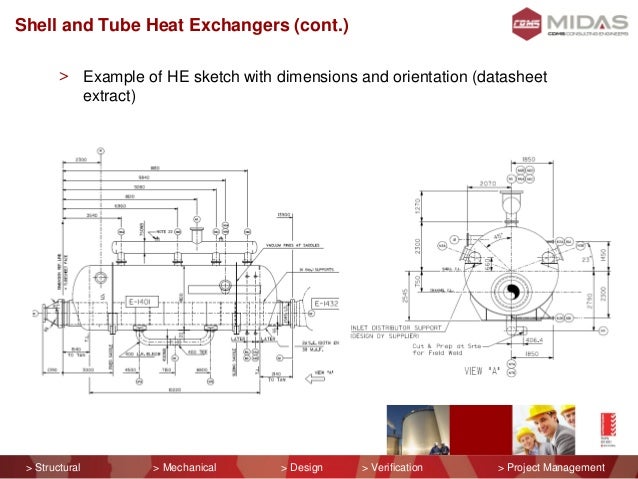

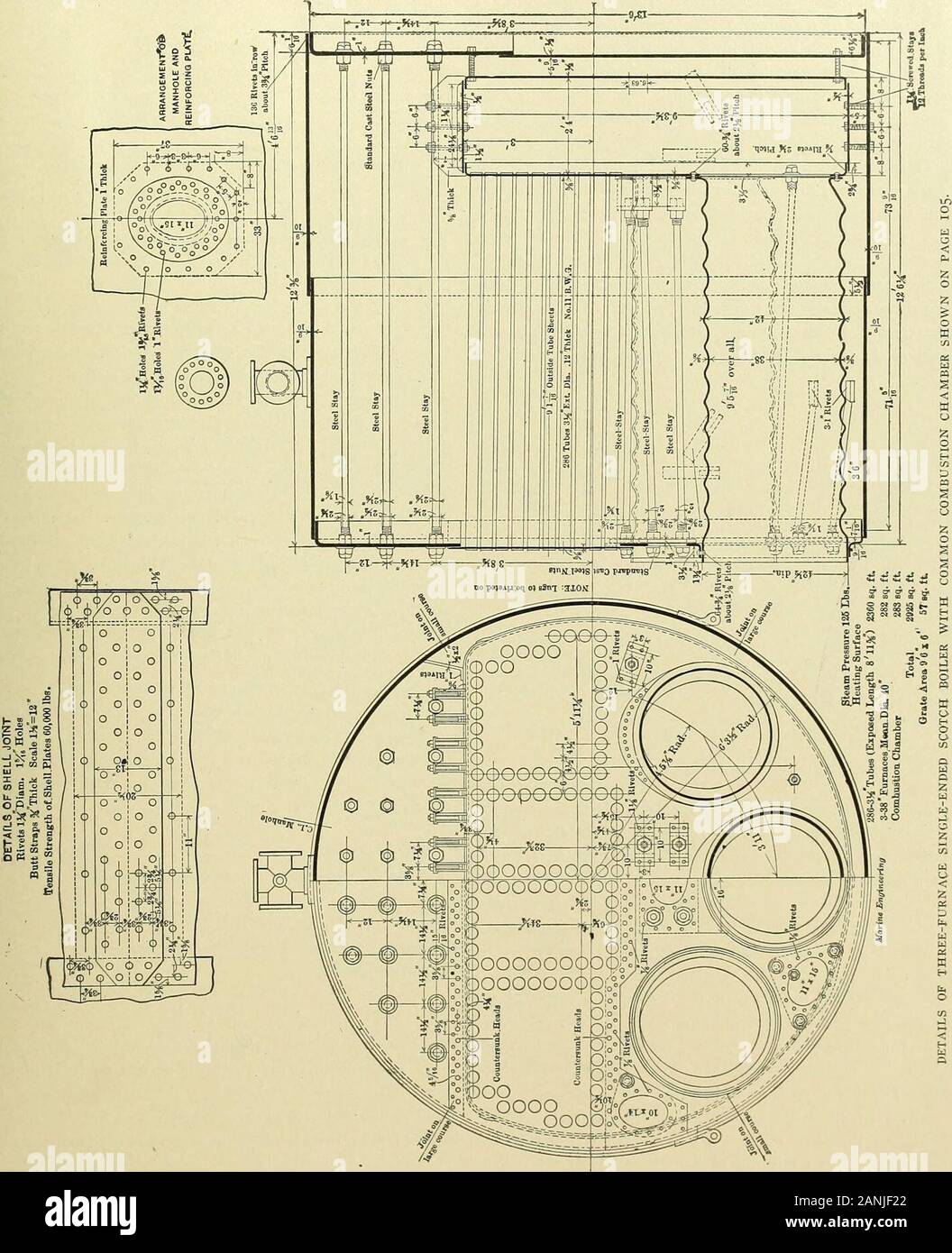

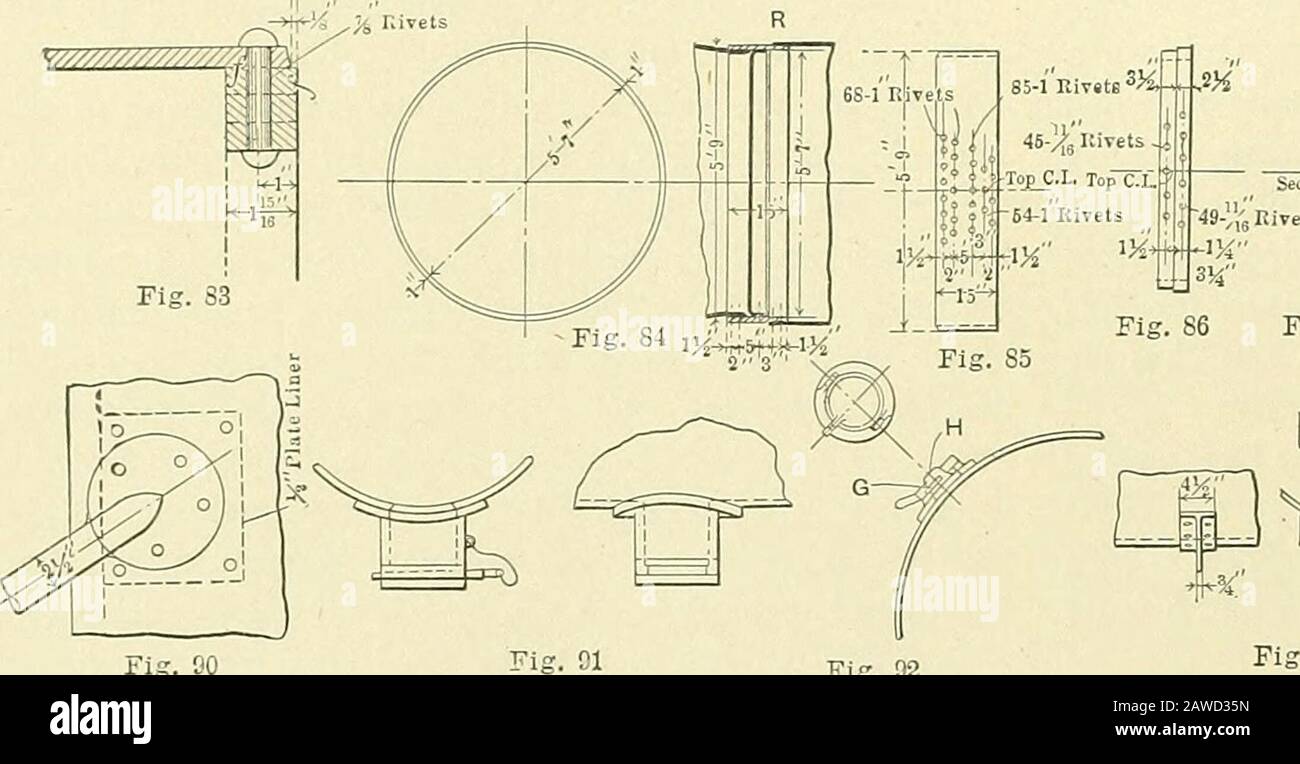

Tubesheet Layout Drawing

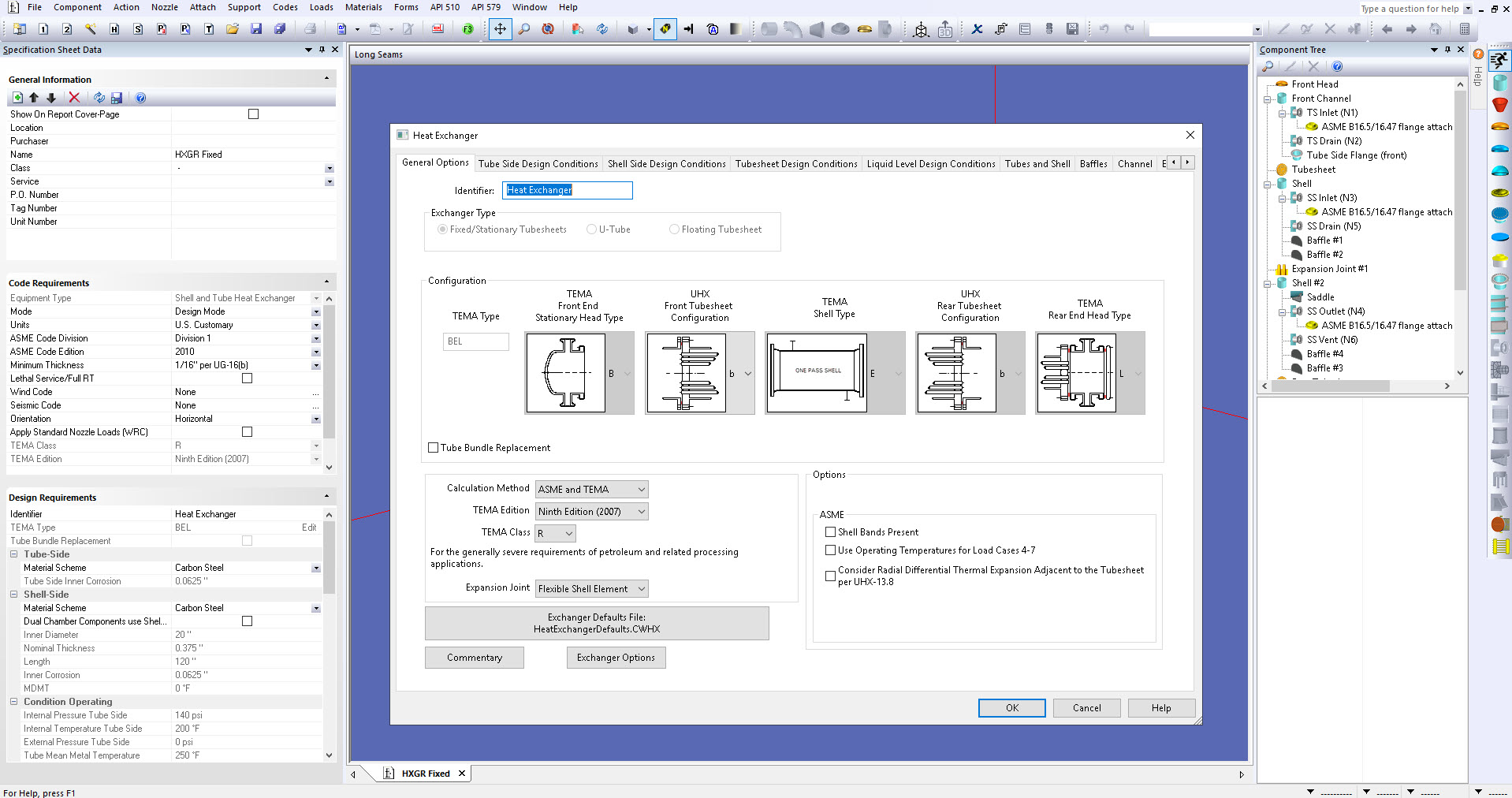

Displays the standard to use for analysis.

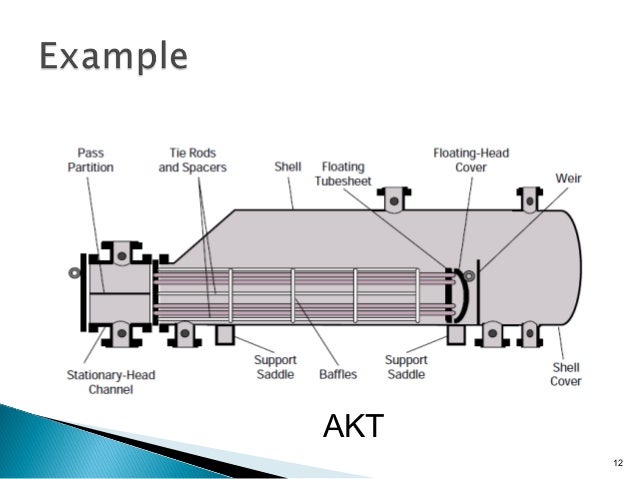

Tubesheet layout drawing. Process design of. Thus floating head shtes can be. Design of tall vessels. 1 tema and bs 5500.

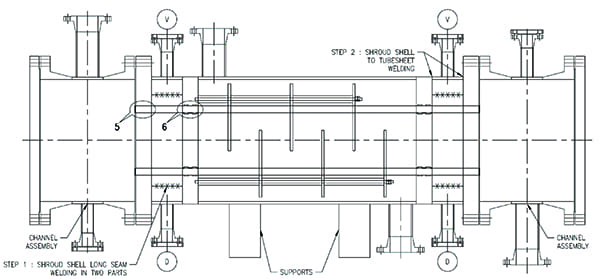

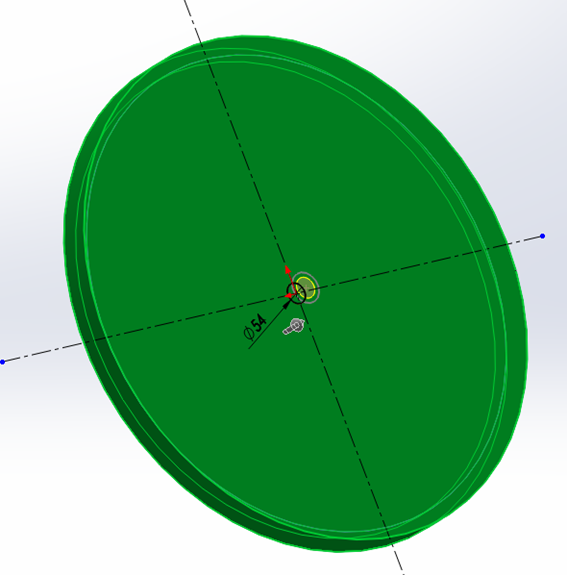

Present analysis and design procedure thoroughly investigates the tubesheet behavior and leads to a thinner tubesheet. Mechanical design of heat exchanger. Part of the design process includes the determination of the amount of tubes to be used in the heat exchanger. This method enables us to calculate stresses in shell and channel in the junction region as well.

If you need asme uhx and tema mechanical design calculations drawings and reports then the compress heat exchanger option is for you. Design engineers have basically two weld options for a tube to tubesheet joint. Also the strength calculation is more difficult. How to draw a 2d pressure vessel tank with torispherical dish end volume calculation tutorial 7 duration.

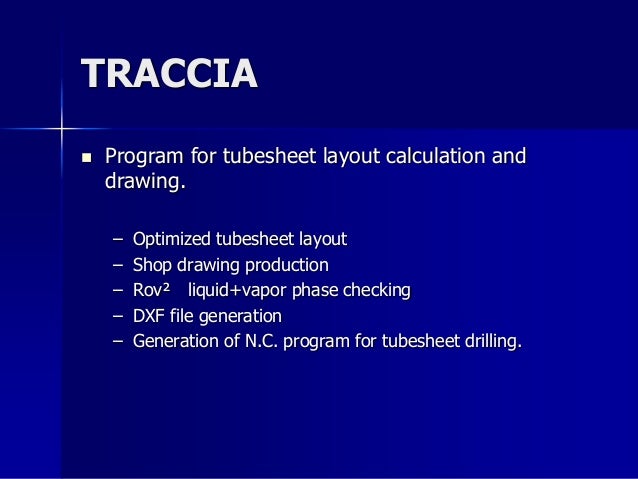

Furthermore the program is validated with open literature and shown good agreement with it. Process design of heat exchanger. Different methods are available for the attachment of the tube end to the tubesheet. Tema tubular exchanger manufacturers association.

Each type of joint has advantages and disadvantages. Regardless of which type you choose it s crucial to use a welding technique that achieves consistent quality. Up to eight design conditions can be investigated for fixed u tube kettle and floating tubesheet style exchangers. Design thickness obtained by this method is compared with the thicknesses calculated using asme sect.

In this design one tubesheet is fixed relative to the shell and the other is free to float within the shell. Industrial cad tutorials 18 768 views. 1 roll or expand with grooves milled in tube holes and seal welded or 2 strength welds no grooves required. Tema gives design rules to calculate the tubesheet thickness which give similar but not identical results to the rules in asme and bs5500.

Asme asme section viii division 1 section uhx or asme section viii division 2 part 4. Shell and tube heat exchangers are complex and more expensive than ordinary pressure vessels. Besides the tubesheet for heat exchangers this method can be extended to the tube counts of sheave plates and perforated plates of distillation column. This permits free expansion of the tube bundle as well as cleaning of both the insides and outsides of the tubes.